Kaltra introduces built-in sequence management for its 2nd generation chillers

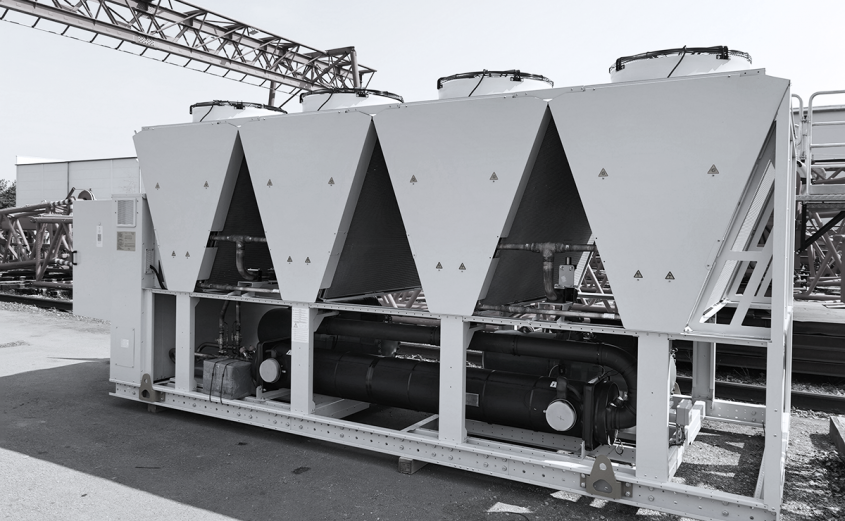

Following numerous performance improvements and enhancing functionality implemented in the latest version of control software installed on second-generation chillers, Kaltra adds sequence management as an option available for air-cooled models equipped with scroll, screw, and Turbocor-based chillers, as well as for chiller versions with free cooling.

Inbuilt sequence manager allows up to 8 units to be networked and acting under the control of dynamically selected master chiller. Functionality includes:

- Load management: load distribution or load sequencing configurations

- Unit rotation based on running hours equalization

- Resource prioritization

- Startup coordination

- Redundancy configurations

- Standby unit control

- Alarm management

Each networked unit can be configured individually, with setting its role, priority, thresholds, rotation rules, and more.

New software is so far available for the following chiller families, in air-cooled and free cooling versions:

For most installations, inbuilt sequence management eliminates the need for expensive and complex stand-alone sequence control, in parallel giving users flexibility in deploying group chiller control.

Chiller sequencing significantly improves the cooling plant performance and enables considerable energy savings, optimizes plant operation, contributes to a longer lifespan of the equipment, and offers extended capabilities in cooling plant control for the users.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 911 253 421 07 or visit www.kaltra.com