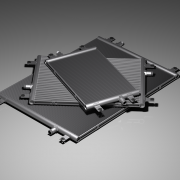

Chilled water coil design enhanced for application flexibility and extended lifespan

As part of its ongoing strategy to expand the applications and market reach of microchannel heat exchangers, Kaltra has introduced a new line of air-to-water microchannel coils, meticulously designed and optimized for specific uses.