Kaltra to modernize its air-cooled Turbocor chiller range

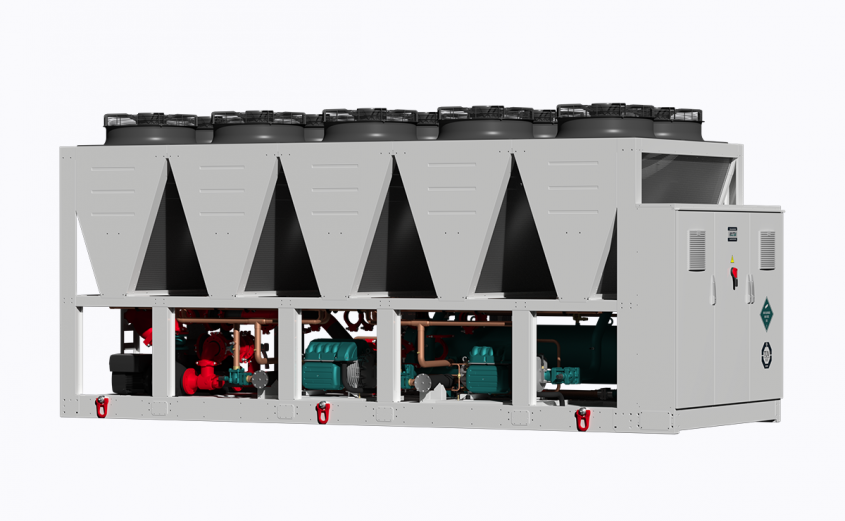

Kaltra, the specialist in air-conditioning and heat transfer technologies, modernized its Turbocor compressor-based chillers with air-cooled condensers and presents performance highlights of the series.

The Lightstream Turbo II series is a unique development in the field of demand-responsive chillers, specially designed for variable-load cooling and optimized for the novel lower-GWP refrigerants R1234ze and R513a.

The series is provided with the Turbocor compressor technology enabling cooling capacity control and resultant optimal energy use in applications. Up to 4 compressors and two refrigeration circuits provide cooling capacity in range to 1350 kilowatt when running on refrigerants R134a and R513a, and up to 1050kW with R1234ze.

Economizers – flash tank type or with a subcooler – available optionally. Four acoustic packages available for selection, as well as packages for operation in extreme cold or hot climates.

Control software optimized for multi-compressor operation and offers extended functionality, advanced energy metering, and remote chiller management. By selecting an efficiency-optimal combination of compressors to cover current cooling demand, control software ensures the lowest possible energy consumption. Compared to the preceding generation, new Turbocor chillers demonstrate about 6 percent higher energy efficiency in cooling load range from 25 to 75%, and quieter operation.

The chillers are designed based on the latest Versa platform, with more than 65% components and assemblies shared between various Kaltra equipment lineups, providing lower initial and after-sales costs for the users.

In Q2 2020, Kaltra plans to adapt Lightstream Turbo II chillers to run with refrigerant R515b – a non-flammable, azeotropic blend of R1234ze and R227ea with global warming potential of as low as 299, aimed at replacing R134a.

In addition to air-cooled design, chillers are also available in a free cooling version with a wide operating envelope, equipped with demand-controlling valves and microchannel cooling coils. Distinguishing features of the system are close approach temperatures making it possible to engage free cooling at higher ambients and its high heat rejection capacity that is supportive of early switching to free cooling-only chiller operation.

Oil-free centrifugal chillers are core products in Kaltra’s market segment, now with modernized Lightstream Turbo II air-cooled models having a leading position in terms of price/performance. Modernized Lightstream Turbo II is an optimum choice for customers whose predominant chiller selection determinants are both purchase costs and long-term benefits of savings in energy consumption.

Headquartered in Germany, Kaltra Innovativtechnik GmbH designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 911 715-32021 or visit www.kaltra.com