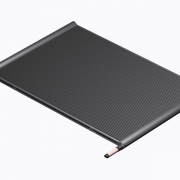

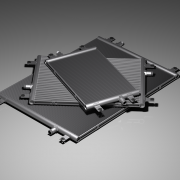

Kaltra creates a leading edge with nanoscale coating for microchannel heat exchangers

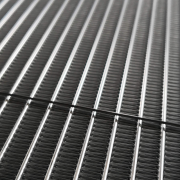

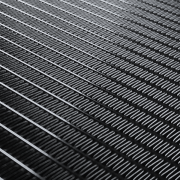

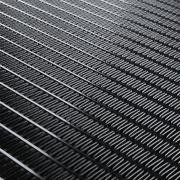

Aluminum is a cornerstone material in microchannel heat exchangers, valued for its lightweight and corrosion-resistant characteristics. However, safeguarding its longevity is crucial. This is where advanced nanoscale coating technology, newly deployed by Kaltra, emerges as a groundbreaking solution, providing unparalleled protection and extending heat exchangers’ performance life.